Table 6.8.1-6 Gas- and Oil-Fired Boilers-Minimum Efficiency Requirements. Table 6.8.1-5 Warm-Air Furnaces and Combination Warm-Air Furnaces/Air-Conditioning Units,Warm-Air Duct Furnaces, and Unit Heaters-Minimum Efficiency Requirements. Table 6.8.1-4 Electrically Operated Packaged Terminal Air Conditioners, Packaged Terminal Heat Pumps, Single-PackageVertical Air Conditioners, Single-Package Vertical Heat Pumps, Room Air Conditioners, and Room Air-Conditioner HeatPumps-Minimum Efficiency Requirements. Table 6.8.1-3 Water-Chilling Packages-Minimum Efficiency Requirementsa,b,e. Table 6.8.1-2 Electrically Operated Air-Cooled Unitary Heat Pumps-Minimum Efficiency Requirements (Continued). Table 6.8.1-2 Electrically Operated Air-Cooled Unitary Heat Pumps-Minimum Efficiency Requirements. Table 6.8.1-1 Electrically Operated Unitary Air Conditioners and Condensing Units-Minimum Efficiency Requirements (Continued). Table 6.8.1-1 Electrically Operated Unitary Air Conditioners and Condensing Units-Minimum Efficiency Requirements. 6.8.1 Minimum Efficiency Requirement Listed Equipment-Standard Rating and Operating Conditions. 6.8 Minimum Equipment Efficiency Tables. Table 6.5.7.2.2 Maximum Net Exhaust Flow Rate, cfm per Linear Foot of Hood Length. Table 6.5.6.1.2-2 Exhaust Air Energy Recovery Requirementsfor Ventilation Systems Operating Greater than or Equal to 8000 Hours per Year. Table 6.5.6.1.2-1 Exhaust Air Energy Recovery Requirementsfor Ventilation Systems Operating Less than 8000 Hours per Year. Table 6.5.4.2 Pump Flow Control Requirements. 6.5.4 Hydronic System Design and Control. Table 6.5.3.1-2 Fan Power Limitation Pressure Drop Adjustment. 6.5.2 Simultaneous Heating and Cooling Limitation. Table 6.5.1.3 DX Cooling Stage Requirements for Modulating Airflow Units. Table 6.5.1.2.1 Fluid Economizer Sizing Dry-Bulb and Wet-Bulb Requirements for Computer Rooms. Table 6.5.1.1.3 High-Limit Shutoff Control Settings for Air Economizersb. Table 6.5.1-1 Minimum Fan-Cooling Unit Size for which an Economizer Is Required. 6.4.5 Walk-In Coolers and Walk-In Freezers. 6.4.4 HVAC System Construction and Insulation. Table 6.4.3.10.1 DDC Applications and Qualifications. Table 6.4.3.4.3 Maximum Damper Leakagea,b, cfm per ft2 at 1.0 in. 6.4.1 Equipment Efficiencies, Verification, and Labeling Requirements.

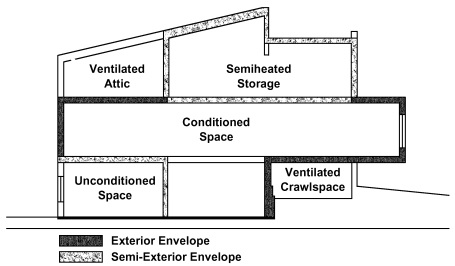

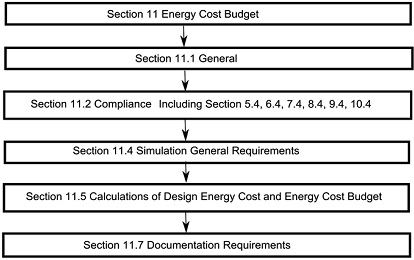

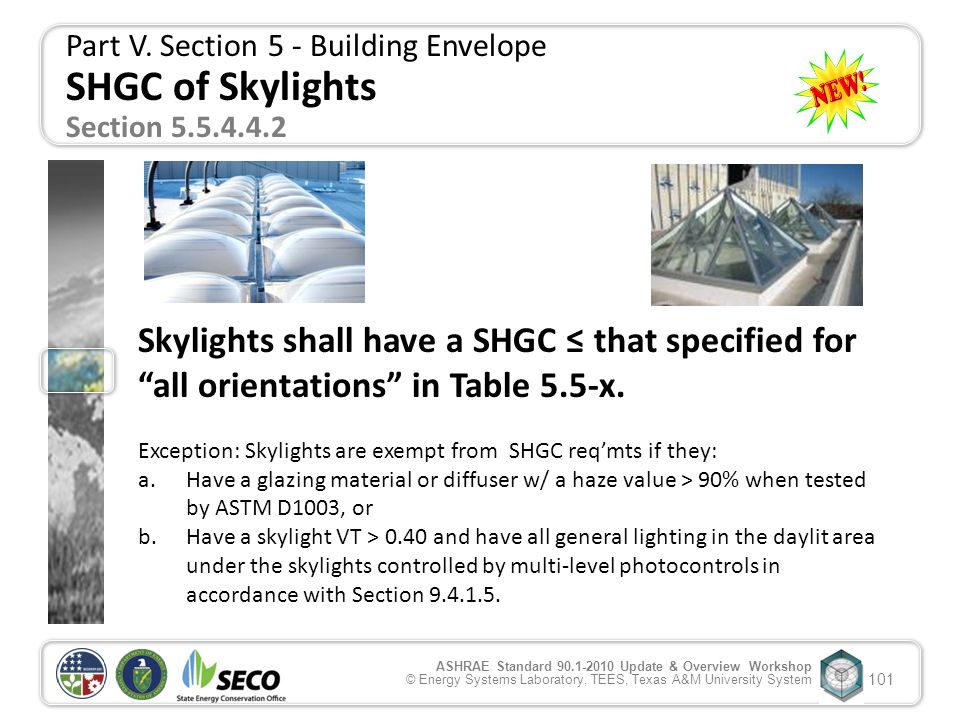

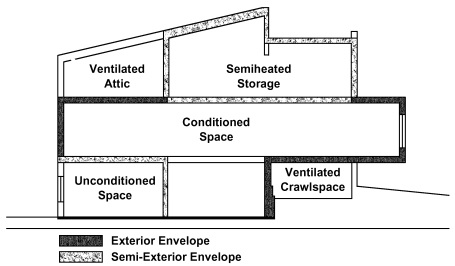

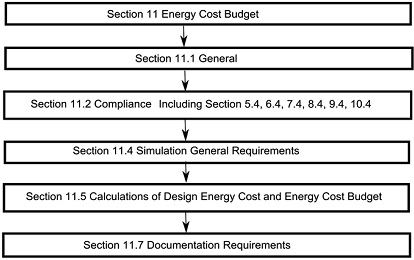

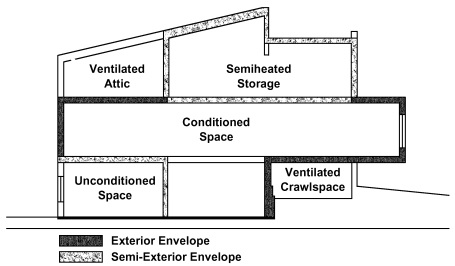

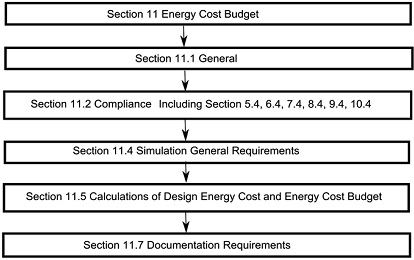

Table 6.8.1-6 Gas- and Oil-Fired Boilers-Minimum Efficiency Requirements. Table 6.8.1-5 Warm-Air Furnaces and Combination Warm-Air Furnaces/Air-Conditioning Units,Warm-Air Duct Furnaces, and Unit Heaters-Minimum Efficiency Requirements. Table 6.8.1-4 Electrically Operated Packaged Terminal Air Conditioners, Packaged Terminal Heat Pumps, Single-PackageVertical Air Conditioners, Single-Package Vertical Heat Pumps, Room Air Conditioners, and Room Air-Conditioner HeatPumps-Minimum Efficiency Requirements. Table 6.8.1-3 Water-Chilling Packages-Minimum Efficiency Requirementsa,b,e. Table 6.8.1-2 Electrically Operated Air-Cooled Unitary Heat Pumps-Minimum Efficiency Requirements (Continued). Table 6.8.1-2 Electrically Operated Air-Cooled Unitary Heat Pumps-Minimum Efficiency Requirements. Table 6.8.1-1 Electrically Operated Unitary Air Conditioners and Condensing Units-Minimum Efficiency Requirements (Continued). Table 6.8.1-1 Electrically Operated Unitary Air Conditioners and Condensing Units-Minimum Efficiency Requirements. 6.8.1 Minimum Efficiency Requirement Listed Equipment-Standard Rating and Operating Conditions. 6.8 Minimum Equipment Efficiency Tables. Table 6.5.7.2.2 Maximum Net Exhaust Flow Rate, cfm per Linear Foot of Hood Length. Table 6.5.6.1.2-2 Exhaust Air Energy Recovery Requirementsfor Ventilation Systems Operating Greater than or Equal to 8000 Hours per Year. Table 6.5.6.1.2-1 Exhaust Air Energy Recovery Requirementsfor Ventilation Systems Operating Less than 8000 Hours per Year. Table 6.5.4.2 Pump Flow Control Requirements. 6.5.4 Hydronic System Design and Control. Table 6.5.3.1-2 Fan Power Limitation Pressure Drop Adjustment. 6.5.2 Simultaneous Heating and Cooling Limitation. Table 6.5.1.3 DX Cooling Stage Requirements for Modulating Airflow Units. Table 6.5.1.2.1 Fluid Economizer Sizing Dry-Bulb and Wet-Bulb Requirements for Computer Rooms. Table 6.5.1.1.3 High-Limit Shutoff Control Settings for Air Economizersb. Table 6.5.1-1 Minimum Fan-Cooling Unit Size for which an Economizer Is Required. 6.4.5 Walk-In Coolers and Walk-In Freezers. 6.4.4 HVAC System Construction and Insulation. Table 6.4.3.10.1 DDC Applications and Qualifications. Table 6.4.3.4.3 Maximum Damper Leakagea,b, cfm per ft2 at 1.0 in. 6.4.1 Equipment Efficiencies, Verification, and Labeling Requirements.  6.3 Simplified Approach Building Compliance Path for HVAC Systems. 6.2.2 Additional Requirements to Comply with Section 6. 6.2.1 Requirements for all Compliance Paths. 6 Heating, Ventilating, and Air Conditioning. 5.9 Verification, Testing, Commissioning, and Inspection. Table 5.8.3.2 Maximum Air Leakage for Fenestration and Doors. Table 5.8.3.1 Maximum Air Leakage for Materials and Assemblies. 5.8 Product Information and Installation Requirements. 5.6 Building Envelope Trade-Off Compliance Path. Table 5.5.4.4.1 SHGC Multipliers for Permanent Projections. Figure 5.5.2 Exterior and semiexterior building envelope. Table 5.5.3.1.1 Increased Roof Insulation Levels. Table 5.5-8 Building Envelope Requirements for Climate Zone 8*. Table 5.5-7 Building Envelope Requirements for Climate Zone 7*. Table 5.5-6 Building Envelope Requirements for Climate Zone 6 (A,B)*. Table 5.5-5 Building Envelope Requirements for Climate Zone 5 (A,B,C)*. Table 5.5-4 Building Envelope Requirements for Climate Zone 4 (A,B,C)*. Table 5.5-3 Building Envelope Requirements for Climate Zone 3 (A,B,C)*.

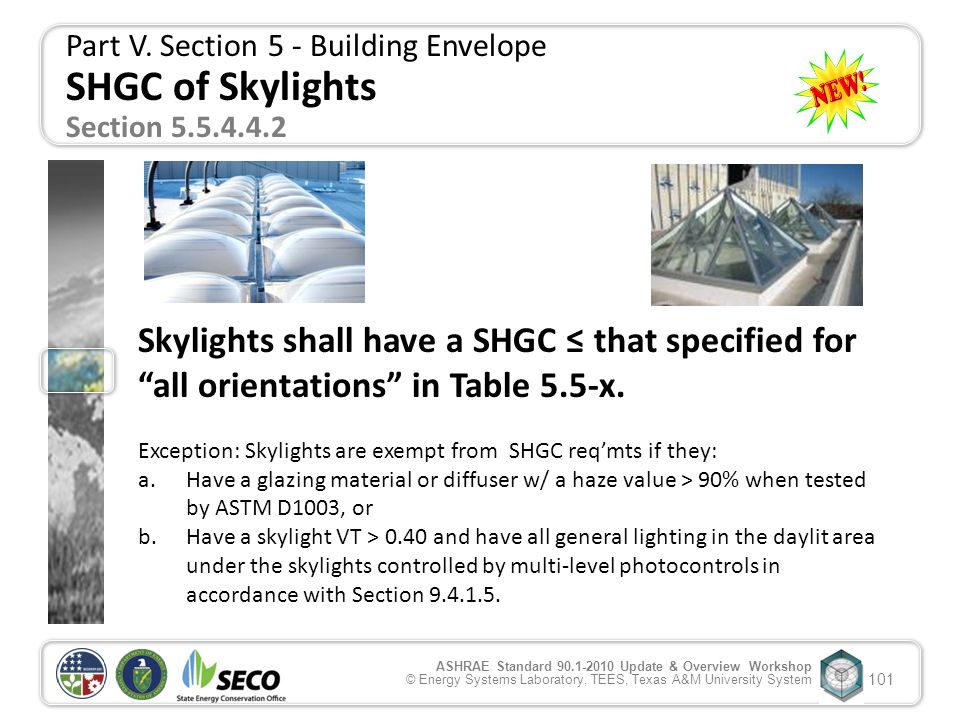

6.3 Simplified Approach Building Compliance Path for HVAC Systems. 6.2.2 Additional Requirements to Comply with Section 6. 6.2.1 Requirements for all Compliance Paths. 6 Heating, Ventilating, and Air Conditioning. 5.9 Verification, Testing, Commissioning, and Inspection. Table 5.8.3.2 Maximum Air Leakage for Fenestration and Doors. Table 5.8.3.1 Maximum Air Leakage for Materials and Assemblies. 5.8 Product Information and Installation Requirements. 5.6 Building Envelope Trade-Off Compliance Path. Table 5.5.4.4.1 SHGC Multipliers for Permanent Projections. Figure 5.5.2 Exterior and semiexterior building envelope. Table 5.5.3.1.1 Increased Roof Insulation Levels. Table 5.5-8 Building Envelope Requirements for Climate Zone 8*. Table 5.5-7 Building Envelope Requirements for Climate Zone 7*. Table 5.5-6 Building Envelope Requirements for Climate Zone 6 (A,B)*. Table 5.5-5 Building Envelope Requirements for Climate Zone 5 (A,B,C)*. Table 5.5-4 Building Envelope Requirements for Climate Zone 4 (A,B,C)*. Table 5.5-3 Building Envelope Requirements for Climate Zone 3 (A,B,C)*.  Table 5.5-2 Building Envelope Requirements for Climate Zone 2 (A,B)*. Table 5.5-1 Building Envelope Requirements for Climate Zone 1 (A,B)*. Table 5.5-0 Building Envelope Requirements for Climate Zone 0 (A,B)*. 5.5 Prescriptive Building Envelope Compliance Path. 5.3 Simplified Building Compliance Path. 5.2.2 Additional Requirements to Comply with Section 5. 5.2.1 Requirements for All Compliance Paths. 4.2.5 Verification, Testing, and Commissioning.

Table 5.5-2 Building Envelope Requirements for Climate Zone 2 (A,B)*. Table 5.5-1 Building Envelope Requirements for Climate Zone 1 (A,B)*. Table 5.5-0 Building Envelope Requirements for Climate Zone 0 (A,B)*. 5.5 Prescriptive Building Envelope Compliance Path. 5.3 Simplified Building Compliance Path. 5.2.2 Additional Requirements to Comply with Section 5. 5.2.1 Requirements for All Compliance Paths. 4.2.5 Verification, Testing, and Commissioning.

4.1.9 Reference Standard Reproduction Annexes. 4.1.3 Alternative Materials, Methods of Construction, or Design. 3 Definitions, Abbreviations, and Acronyms.